Which do you choose - Drill vs Impact Driver

Today we will discuss the difference between a drill and an impact driver. Many people may be confused when choosing tools and don't know which tool to choose, which may lead to poor progress in work or poor quality of work by choosing the wrong tool.

I hope that through this article, you will have a deep understanding of the difference between an electric drill and an impact driver, so that you can know whether you should choose an electric drill or an impact driver the next time you perform work, and which tool is the most commonly used.

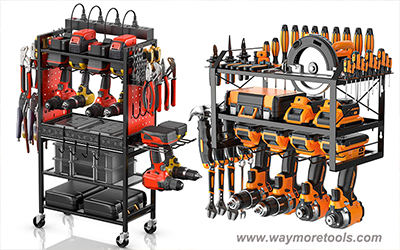

Typically, drills and impact drivers are sold together, and I recommend when choosing a tool that you consider buying a set of both, or even a combo set that includes several other tools.

First, let's discuss electric drills. The drill bit of an electric drill is relatively large and wide. It usually has three claws to grasp the drill bit and can adapt to different types of drill bits, such as woodworking twist drills or cement drill bits. Electric drills can also be used to drive screws. Some electric drills have a knocking function and are suitable for knocking cement or using diamond drill bits. Additionally, a power drill can be used to remove particles from wood surfaces or use screw heads.

As for the impact driver, it's relatively simple and just pops in and locks. When using an impact driver, you simply place it into your work area and it locks automatically without the need to pull the prongs like a power drill. Impact drivers are also suitable for collar screws, especially if they engage in impact mode when a certain amount of resistance is encountered.

Another difference between a power drill and an impact driver lies in how they work. The main function of an electric drill is to continuously provide power, while an impact driver will switch to impact mode when encountering a certain resistance, using a small hammer to strike vertically. This makes the impact driver more effortless in tasks that require extra force, such as tightening screws.

Above we talked about some details of electric drills and impact drivers, such as adjusting speed, strength, working depth, etc. An impact driver may be more convenient in some specific situations, especially when removing or installing screws. Its vertical strength can better handle some screws that are difficult to remove.

Overall, both electric drills and impact drivers have their own advantages, and the choice depends on the specific job needs. In actual work, impact screwdrivers are more widely used, and impact screwdrivers are chosen in 95% of cases.

Okay, the above is a summary of the application scenarios of impact drivers and electric drills. We also know the differences between them in work. I hope everyone can learn how to use these two tools flexibly in actual work. Thank you!

If you have any questions or if there's anything specific you would like to discuss further, feel free to let me know!

Waymore Tools

Waymore Tools