Table of Contents

- Introduction

- Understanding the Basics of Power Drills

- Types of Power Drills

- Choosing the Right Power Drill for Your Needs

- Tips for Using a Power Drill

- Advanced Techniques for Power Drill Mastery

- Common Problems and Troubleshooting Tips

- Maintenance Tips for Longevity

- Conclusion

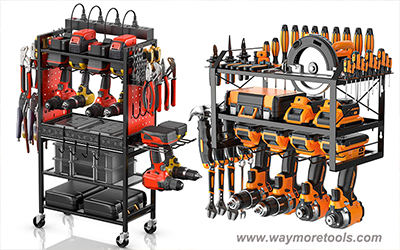

Introduction

Ready to elevate your DIY game? The power drill is your trusty sidekick, a versatile and indispensable tool that can transform your projects from daunting to doable. Whether you're hanging shelves, building furniture, or tackling home repairs, a power drill can be your best friend. This guide dives deep into everything you need to know about this essential tool, from understanding its basic components to mastering advanced techniques for unleashing its full potential.

Understanding the Basics of Power Drills

What is a Power Drill?

Think of a power drill as the Swiss Army knife of tools. This handheld marvel, powered by electricity, drills holes or drives fasteners into wood, metal, plastic—you name it. At its core, a power drill consists of several key components: the motor, chuck, trigger, and clutch.

Components of a Power Drill

- Motor: At the heart of the power drill, the motor converts electrical energy into mechanical motion. It's what gives the drill its power and speed.

- Chuck: This is the part of the drill that holds the drill bit or driver bit. Chucks come in various sizes, with 3/8-inch and 1/2-inch being the most common.

- Trigger: The trigger controls the drill's speed. Squeeze it gently for a slow spin or pull it fully for maximum speed.

- Clutch: The clutch, also known as the torque selector, allows you to control the amount of torque (rotational force) applied by the drill. This is particularly useful for driving screws to a consistent depth without stripping them.

How Does a Power Drill Work?

When you press the trigger, the motor powers up, causing the chuck to rotate. Depending on the bit attached, the drill can either create holes or drive screws. The clutch settings help you adjust the torque, ensuring that you don't overdrive screws or damage the material you're working with.

Types of Power Drills

Cordless Drills

Cordless drills are all about freedom and flexibility. Powered by rechargeable batteries, these bad boys let you work anywhere without being tethered to an outlet. This makes them ideal for projects where outlets are out of reach or when you're working in tight spaces.

Advantages of Cordless Drills

- Portability: Take them anywhere without worrying about power sources.

- Convenience: Quick and easy to use, perfect for light to medium-duty tasks.

- Versatility: Suitable for a wide range of applications, from drilling holes to driving screws.

Disadvantages of Cordless Drills

- Battery Life: Limited by the battery's charge, which can be a hassle during long projects.

- Power: Generally less powerful than their corded counterparts, making them less suitable for heavy-duty tasks.

Hammer Drills

When concrete or masonry stands in your way, hammer drills step up. These drills combine the rotational motion of a standard drill with a hammering action that delivers rapid, short thrusts to pulverize tough materials. If you're planning to drill into concrete walls or lay anchor bolts, a hammer drill is your go-to tool.

Advantages of Hammer Drills

- Power: Capable of drilling through hard materials like concrete and brick.

- Efficiency: Makes quick work of tough drilling tasks that would be arduous with a standard drill.

Disadvantages of Hammer Drills

- Weight and Size: Generally larger and heavier, which can be cumbersome for extended use.

- Cost: Typically more expensive than standard drills due to their specialized function.

Impact Drivers

Need to drive screws like a pro? Impact drivers deliver high torque for heavy-duty tasks, making them your go-to for serious fastening. Unlike standard drills, impact drivers use concussive rotational blows to drive screws and bolts with ease. They're particularly effective for driving long screws or bolts into hard materials without stripping the heads.

Advantages of Impact Drivers

- Torque: Provides significantly more torque than standard drills, perfect for tough driving tasks.

- Control: Reduces the risk of cam-out (slipping out of the screw head), ensuring a secure fit.

Disadvantages of Impact Drivers

- Specialization: While great for driving screws, they are not as versatile as standard drills for other tasks.

- Noise: Generally louder than standard drills due to the impact mechanism.

Choosing the Right Power Drill for Your Needs

With several types of power drills available, how do you choose the right one for your needs? Here are some factors to consider:

- Purpose of Use: Think about the primary tasks you'll be performing. If you're mainly drilling holes and driving screws into wood or light materials, a cordless drill might be sufficient. For heavy-duty tasks involving concrete or masonry, a hammer drill is a better choice. If driving screws and bolts is your main focus, an impact driver is the way to go.

- Power Source: Consider whether you need the portability of a cordless drill or the sustained power of a corded drill. Cordless drills offer convenience but are limited by battery life. Corded drills provide continuous power but require access to an electrical outlet.

- Budget: Power drills come in a wide range of prices. Set a budget and choose a drill that offers the best features within your price range. Remember, higher-priced models often come with additional features and better build quality.

- Ergonomics: Comfort is key, especially for extended use. Look for a drill with a comfortable grip and balanced weight. Some models also offer ergonomic features like rubberized grips and adjustable handles.

Tips for Using a Power Drill

Maximize your power drill's potential with these handy tips:

- Select the Right Bit: Match your bit to your material—wood, metal, or concrete. Using the wrong bit can spell disaster for your project and your tool. Here's a quick guide to choosing the right bit:

- Twist Bits: Ideal for general-purpose drilling in wood, plastic, and metal.

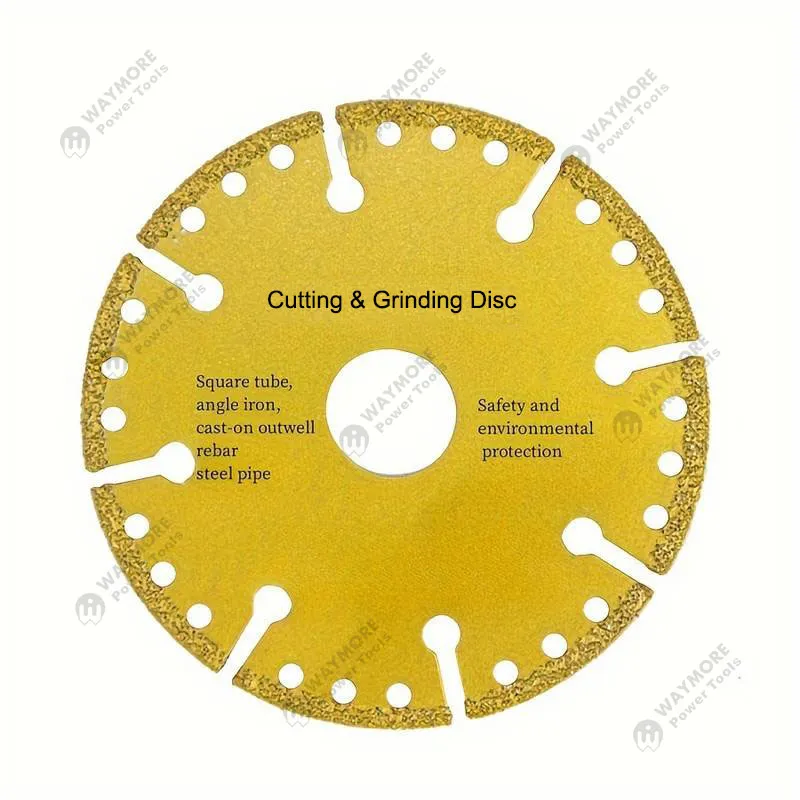

- Masonry Bits: Designed for drilling into concrete, brick, and stone.

- Spade Bits: Great for drilling large holes in wood.

- Hole Saws: Perfect for cutting large-diameter holes in wood and metal.

- Adjust the Speed and Torque: Dial in the right speed and torque for the job. Higher speeds excel at drilling, while lower speeds are ideal for driving screws. Here are some general guidelines:

- High Speed, Low Torque: Best for drilling small holes in wood and metal.

- Low Speed, High Torque: Ideal for driving screws and drilling large holes.

- Practice Safety Precautions: Safety first! Do wear those goggles and gloves. And always secure your workpiece to keep accidents at bay. Here are some additional safety tips:

- Keep Your Workspace Clean: A cluttered workspace can lead to accidents. Keep it tidy.

- Use the Right Accessories: Always use bits and accessories that are compatible with your drill.

- Check for Obstacles: Before drilling, check for electrical wires, pipes, and other obstacles behind walls.

Advanced Techniques for Power Drill Mastery

Ready to take your skills to the next level? Here are some advanced techniques to help you master your power drill:

- Countersinking: Countersinking creates a conical hole for the screw head to sit flush with the surface. This technique is essential for creating a clean, professional finish. To countersink, use a countersink bit after drilling your pilot hole.

- Pilot Holes: Drilling pilot holes before driving screws can prevent wood from splitting and make driving screws easier. Use a bit slightly smaller than the screw diameter for best results.

- Depth Stop: When you need to drill holes to a specific depth, a depth-stop attachment can help. This accessory ensures that you drill to the exact depth needed, preventing over-drilling.

- Angle Drilling: Sometimes, you need to drill at an angle. Angle drilling guides or attachments can help you maintain the correct angle, ensuring precise results.

Common Problems and Troubleshooting Tips

Even with the best tools, problems can arise. Here are some common issues and how to troubleshoot them:

- Drill Bit Slipping: If your drill bit slips in the chuck, it might not be tightened properly. Make sure to secure the bit firmly in the chuck. If the problem persists, the chuck might be worn out and need replacement.

- Overheating: Drills can overheat during extended use. To prevent this, take breaks to let the drill cool down. Overheating can damage the motor, so it's important to monitor the drill's temperature.

- Battery Life: Cordless drill batteries can run out of juice quickly, especially during heavy use. To extend battery life, fully charge the battery before use and avoid over-discharging. Keeping a spare battery on hand can also help minimize downtime.

- Poor Performance in Hard Materials: If your drill struggles with hard materials, make sure you're using the right bit and drill settings. For materials like concrete, a hammer drill with a masonry bit is essential.

Maintenance Tips for Longevity

Proper maintenance can extend the life of your power drill and keep it performing at its best. Here are some maintenance tips:

- Regular Cleaning: After each use, clean your drill to remove dust and debris. Use a soft cloth and, if necessary, a brush to clean hard-to-reach areas.

- Lubrication: Periodically lubricate the chuck and other moving parts to keep them operating smoothly. Check your drill's manual for specific lubrication recommendations.

- Battery Care: For cordless drills, proper battery care is crucial. Store batteries in a cool, dry place and avoid overcharging. If you have multiple batteries, rotate them to even out usage.

- Inspection: Regularly inspect your drill for signs of wear and tear. Check the power cord for damage, ensure the chuck is functioning properly, and replace worn bits and accessories.

Conclusion

In the end, a power drill isn't just a tool—it's a game-changer for your DIY endeavors. Whether you're a seasoned pro or a weekend warrior, understanding its parts, mastering its types, and following best practices can unlock a world of precision and efficiency. So, grab that power drill and transform your projects with confidence and flair. Happy drilling!

Your power drill is more than just a tool; it's an extension of your creativity and craftsmanship. By mastering its use, you can tackle any project with ease and confidence. From simple home repairs to complex construction tasks, the power drill is your ally in achieving DIY success. So, the next time you pick up your power drill, remember the tips and techniques from this guide and let your projects soar to new heights.

Waymore Tools

Waymore Tools

Leave a Comment