Introduction:

In recent years, laser levels have emerged as a game-changer in the construction industry, providing unparalleled accuracy and convenience in leveling, alignment, and layout tasks. This article explores the evolution of laser levels, their current capabilities, and how they are shaping the future of construction.

I. The Journey from Traditional to Laser Levels

A. The History of Leveling Tools

Traditional leveling tools such as spirit levels and plumb bobs have been essential in construction, surveying, and engineering for centuries. These tools ensure that structures are built on a level surface and vertical elements are plumb. While laser technology has significantly improved the efficiency and accuracy of leveling tasks in construction, traditional leveling tools continue to be used for their simplicity, affordability, and reliability in various applications where high precision is not the primary concern.

B. The Invention of Laser Levels

The development of laser technology has been a transformative force in the construction industry. It has greatly improved the efficiency and accuracy of leveling and alignment tasks. As technology continues to evolve, laser levels are expected to play an even more crucial role in the industry, contributing to the construction of safer, more precise, and more efficient buildings and structures.

C. The Evolution of Laser-Level Technology

The progression of laser levels from basic models to more advanced self-leveling, cross-line, and rotary lasers reflects the continuous innovation and adaptation of technology to meet the evolving needs of the construction industry. Laser levels have become more user-friendly, accurate, and versatile, catering to a broader range of construction tasks. Additionally, the integration of digital technology, wireless capabilities, and advanced software has further enhanced their functionality, making them indispensable tools in modern construction practices.

II. The Science Behind Laser Levels

A. How Laser Levels Work

Laser levels work based on the principle of light amplification by stimulated emission of radiation (LASER). This process was first proposed by Albert Einstein in 1916. Laser technology provides a highly precise and convenient tool for construction, surveying, and other applications where accurate leveling and alignment are crucial.

B. Accuracy and Precision

Laser levels offer significantly higher accuracy compared to traditional leveling tools due to several scientific factors. These factors include the coherent and monochromatic nature of laser light, high beam quality, self-leveling capabilities, digital readouts, calibration methods, and environmental stability. All these factors combined provide a level of precision that traditional leveling tools cannot match, making laser levels an essential tool in modern construction and surveying practices.

C. The Role of Digital Readouts

The integration of digital technology in laser levels has significantly enhanced their precision, functionality, and ease of use. This has revolutionized their capabilities, providing enhanced precision, user-friendliness, and efficiency. These advancements have made laser levels more versatile and reliable tools for professionals in the construction and surveying industries, contributing to the overall quality and speed of construction projects.

III. Applications Across Industries

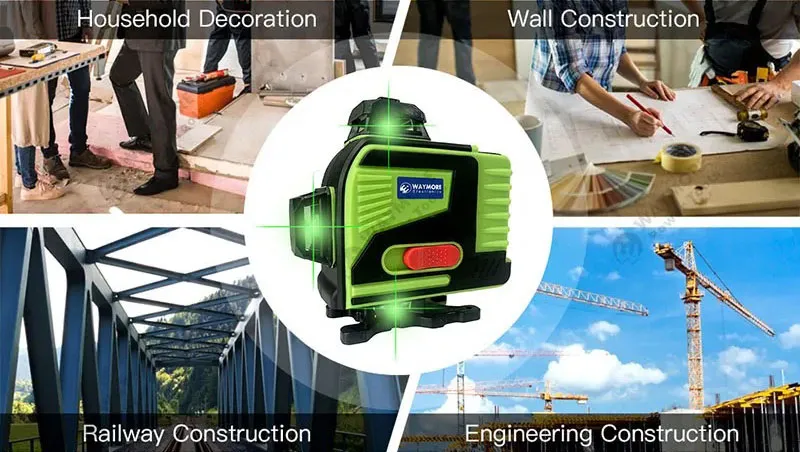

A. Construction and Civil Engineering

Laser levels are crucial in building construction, infrastructure projects, and civil engineering works due to their high precision and efficiency. They are used in various stages of these projects to ensure accuracy and quality in construction and engineering tasks. Laser levels have a wide range of applications, including site surveying and layout, foundation work, wall framing and installation, flooring and tiling, integration with BIM and CAD, and safety and ergonomics. They are versatile and indispensable tools in the construction and civil engineering industries. They contribute to the accuracy, efficiency, and safety of construction projects, ensuring that structures are built to precise specifications and that quality standards are met throughout the construction process.

B. Interior Design and Home Improvement

Laser levels are not only essential in large-scale construction projects but also play a significant role in interior design tasks, where precision and aesthetics are paramount. Laser levels assist in various interior design tasks, including hanging artwork and wall decorations, installing cabinets and shelves, flooring installation, room layout and furniture placement, aligning windows and doors, drywall installation, lighting and electrical installation, and plumbing and HVAC. Laser levels are valuable tools in interior design, providing a level of precision that enhances the quality and appearance of finished spaces. They save time, reduce the potential for errors, and contribute to a more efficient and satisfying design process.

C. Surveying and Land Measurement

Laser levels, particularly Terrestrial Laser Scanners (TLS), have revolutionized the field of surveying, particularly in land measurement and topographical analysis. Laser levels have a wide range of applications, including topographic surveying, data collection speed, accuracy and precision, integration with GIS and BIM, structural deformation monitoring, non-destructive testing, environmental surveys, and infrastructure projects. Laser levels play a vital role in modern surveying practices, providing fast, accurate, and detailed data for land measurement and topographical analysis. Their versatility and precision have made them indispensable tools for a wide range of applications, from urban development to environmental conservation and infrastructure management.

IV. Benefits of Using Laser Levels

A. Time and Labor Efficiency

The use of laser levels has significantly reduced the time and labor required for leveling tasks across various industries, particularly in construction and surveying. The use of laser levels has revolutionized leveling tasks by reducing the time and labor required, increasing accuracy, and improving overall efficiency. These benefits have made laser levels an indispensable tool in modern construction, surveying, and other industries where precise leveling is essential.

B. Enhanced Accuracy and Quality

Laser levels have had a significant impact on the overall quality of construction projects by enhancing precision, efficiency, and consistency in various aspects of the construction process. Laser levels contribute to improved construction quality by increasing accuracy, efficiency in leveling tasks, quality control and compliance, reducing rework, integrating with advanced technologies, enhancing safety, improving collaboration, and ensuring long-term structural integrity. Laser levels have revolutionized the construction industry by providing a level of precision and efficiency that was previously unattainable. This has led to improved quality control, reduced rework, enhanced safety, and better collaboration among construction professionals, ultimately resulting in higher-quality construction projects.

C. Safety and Ergonomics

The use of laser levels has significantly improved safety and ergonomics for construction workers compared to traditional leveling methods, which often involve manual measurements and physical strain. The adoption of laser levels has led to a notable improvement in the safety and ergonomics of construction work. By reducing physical strain, eliminating risky tasks, and improving the overall working environment, laser levels contribute to a healthier and more productive construction industry.

V. Choosing the Right Laser Level

There are many different types of laser levels available on the market designed to cater to various construction, surveying, and DIY needs. These include rotary lasers, cross-line lasers, self-leveling laser levels, and multi-line laser levels, each with unique features and applications. To select the right laser level for a project, users must consider factors such as the accuracy and range required, the type of task to be performed, the level of automation required, the user's experience and skill level, and the budget.

As technology advances, laser levels continue to evolve, offering more accuracy, convenience, and integration with other tools and software. To ensure accurate and reliable measurements in construction and DIY projects, it's essential to maintain the longevity and performance of laser levels. By following maintenance tips available in the manual book, users can extend the lifespan of their laser level and ensure it continues to provide accurate and reliable measurements for their projects. Regular care and attention will help users avoid costly repairs or replacements and keep their laser level functioning at its best.

VI. The Future of Laser Levels

A. Advancements in Technology

Laser levels have undergone significant technological advancements that have enhanced their functionality, user experience, and integration with other tools and software. Some of the key developments include Bluetooth connectivity, app integration, advanced self-leveling mechanisms, digital readouts and displays, longer battery life, improved beam visibility, durability, and rugged design, and integration with robotic systems.

These technological advancements have made laser levels more versatile, user-friendly, and efficient, further solidifying their role as indispensable tools in the construction, surveying, and engineering industries. As technology continues to evolve, we can expect even more innovative features and improvements in the future.

B. Industry Trends

The construction industry expects the evolution of laser levels to continue at a rapid pace, driven by advancements in technology and the increasing demands of the industry. The future of laser levels looks promising, with continuous technological advancements set to enhance their capabilities, efficiency, and user experience. These developments will not only improve the quality and speed of construction projects but also contribute to a safer and more sustainable built environment.

C. Sustainability and Environmental Impact

Laser levels play a significant role in promoting sustainable construction practices by enhancing efficiency, reducing waste, and improving the overall quality of construction projects. By improving accuracy, efficiency, and resource management, laser levels are instrumental in promoting sustainable construction practices. Their integration with advanced technologies like BIM and 3D laser scanning further enhances their role in creating environmentally friendly and energy-efficient buildings. As the construction industry continues to prioritize sustainability, the use of laser levels is expected to grow, contributing to a greener and more responsible built environment.

Conclusion:

Laser levels have revolutionized the construction industry by offering a level of precision and efficiency that was once unimaginable. As technology continues to advance, these devices are expected to become even more integral to the construction process, driving innovation and setting new standards for quality and safety. For professionals in the industry, investing in a high-quality laser level is not just a smart choice; it's a necessity for staying competitive in an ever-evolving market.

Waymore Tools

Waymore Tools