Today's Insights: Understanding Precision in Wholesale Laser Levels: A Guide for Industry Professionals

Importance of Precision in Laser Levels

In today's competitive construction and surveying market, precision is paramount. As importers and distributors of laser levels, we understand that accuracy isn't just a specification – it's a promise to our customers. The laser level market has evolved significantly, with technological advancements pushing the boundaries of precision while making these essential tools more accessible than ever. Whether you're sourcing budget-friendly options or premium models, understanding the factors that influence laser level precision is crucial for making informed business decisions. Explore our selections of laser levels to meet your needs.

Core Factors Affecting Laser Level Precision

The foundation of laser level accuracy lies in several key technological components. At its core, a laser level's precision is determined by beam divergence and beam drift. As the laser beam travels over distance, natural spreading occurs, which can affect accuracy. High-quality laser levels typically maintain an accuracy of ±1/16 inch at 100 feet, which is approximately ten times more precise than traditional spirit levels.

Manufacturing quality plays a crucial role in maintaining this precision. Modern laser levels utilize advanced optical components and precision manufacturing techniques to minimize beam distortion and ensure consistent accuracy. The self-leveling mechanism, a critical component in today's laser levels, automatically adjusts to maintain accuracy within a specified range, typically 3 degrees.

Manufacturing Quality: Budget vs. Premium Laser Levels

The distinction between budget and premium laser levels goes beyond price point. While budget-friendly options typically range from $20 to $100, making them accessible for basic applications, they often come with limitations. These can include reduced accuracy over longer distances, dimmer laser lines, and potentially shorter lifespans.

Premium laser levels, on the other hand, incorporate higher-quality components and more robust construction. They often feature:

- Advanced self-leveling motors for consistent accuracy

- Superior beam quality for enhanced visibility

- Durable aluminum housings and shatterproof glass optics

- Extended warranty coverage, often 3-5 years

For our range of premium options, visit our laser level collection.

External Influences on Laser Level Performance

Environmental factors significantly impact laser level accuracy. Temperature fluctuations, humidity, and atmospheric conditions can affect beam propagation. For instance, extreme temperatures can influence internal components, while dust particles can scatter the laser beam.

To maintain optimal performance, consider these key factors:

- Stable atmospheric conditions are crucial for accurate measurements

- Direct sunlight can affect beam visibility

- Vibrations from nearby equipment can impact accuracy

- Surface stability affects measurement reliability

Selecting the Right Laser Level for Your Market

When choosing laser levels for your inventory, consider your target market's specific needs. Construction professionals typically require durable laser levels with features like dust and water resistance. Interior designers and renovation specialists might prefer cross-line laser levels for smaller, indoor projects.

Consider these market-specific factors:

- Range requirements (50-100 feet for interior work, 500+ feet for outdoor projects)

- Accuracy requirements (typically ±1/16 to ±1/8 inch at 100 feet for professional use)

- Environmental conditions where the tools will be used

- Battery life and power source options

For a variety of options tailored to your needs, check out our selection of laser levels.

Quality Control and Standards for Importers

For importers and distributors, maintaining quality control is essential. Compliance with international standards ensures product reliability and builds trust with customers. Manufacturers must self-certify that each product meets requirements through thorough testing.

Regular calibration and testing procedures should be implemented to:

- Verify accuracy specifications

- Ensure compliance with safety standards

- Maintain consistent quality across shipments

- Document performance metrics

Addressing Common Customer Concerns

Common customer issues often relate to accuracy and reliability. Understanding these concerns helps in providing better customer support and selecting appropriate inventory. The most frequent issues include:

- Power and battery problems

- Accuracy and calibration issues

- Visibility challenges in bright conditions

- Self-leveling malfunctions

To address these concerns proactively, provide clear documentation, proper training materials, and reliable customer support.

Market Trends and Future Developments

The laser level industry continues to evolve with technological advancements. Current trends include:

- Integration of digital technology with traditional levels

- Development of more accurate and stable laser systems

- Introduction of green beam technology for better visibility

- Smart features like Bluetooth connectivity and remote operation

The global line laser level market is experiencing growth driven by increased construction activities and infrastructure development. Future developments are expected to focus on improved accuracy, enhanced durability, and expanded feature sets.

Conclusion

Understanding the precision factors in laser levels is crucial for success in the wholesale and distribution market. By carefully considering manufacturing quality, environmental influences, and market needs, we can make informed decisions that benefit both our business and customers. As technology continues to advance, staying informed about industry trends and maintaining high-quality standards will be key to meeting evolving customer demands.

Ready to elevate your laser level inventory? Contact us today to learn more about our premium selection of laser levels and how we can help you meet your customers' precision needs. Our team of experts is here to guide you through the selection process and ensure you have the right tools for your market.

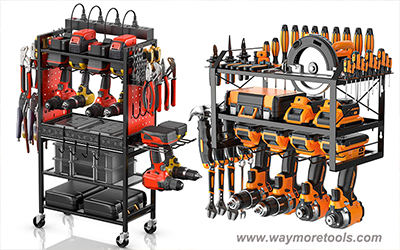

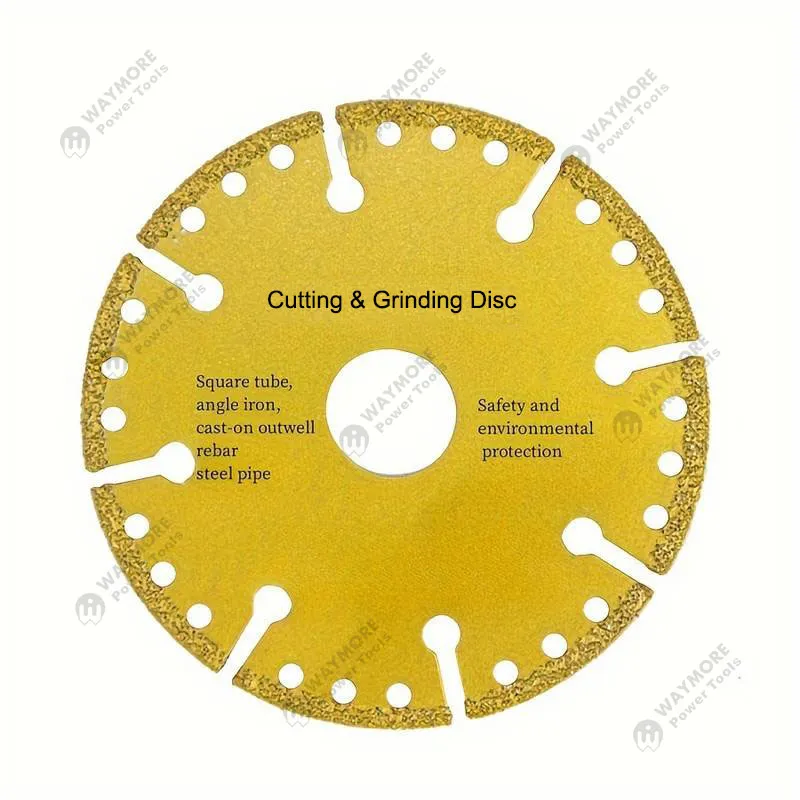

As our company continues to participate in this grand event, we remain committed to offering the best power tools and machinery solutions to meet the needs of our global partners. Whether you are a wholesaler, importer, or distributor, we are ready to collaborate and support your business growth.

If you are interested in our Power Tools, welcome to contact with us, and we are here to offer you best service and great products, thank you!

Contact: Daniel

Email: daniel@waymoretools.com

Website: www.waymoretools.com

Waymore Tools

Waymore Tools