Today's Insights: End-of-Year Laser Level Maintenance: Essential Guide for Industry Professionals

Understanding the Critical Nature of Year-End Care

Year-end maintenance represents more than just routine upkeep - it's a strategic investment in your equipment's longevity and reliability. Industry research demonstrates that implementing proper maintenance protocols can significantly reduce equipment failures and extend operational life.

For laser levels, preventive maintenance becomes particularly crucial during the off-season, helping to prevent workplace equipment failures and costly project delays.

Essential Maintenance Procedures

The maintenance process for laser levels requires a methodical approach. Key areas include:

- Cleaning Protocol: Use a microfiber cloth for gentle cleaning of the laser lens to avoid scratches that can affect accuracy.

- Calibration: Check calibration every 3-6 months. Professional calibration services can ensure your equipment maintains its precision.

Professional Servicing Advantages

Engaging professional service providers during the off-season offers faster turnaround times and thorough diagnostics. Certified technicians can inspect components like the laser diode, power systems, and leveling mechanisms to identify potential issues early.

Storage Protocol for Extended Periods

Proper storage during downtime is essential. Always store laser levels in their designated cases, remove batteries to prevent leakage, and maintain consistent temperature and humidity levels.

Building Strong Supplier Relationships

Maintaining strong relationships with suppliers provides access to warranty coverage, genuine replacement parts, and technical support. Using authentic components is crucial for equipment accuracy and warranty retention.

Future-Proofing Your Investment

Regular maintenance during year-end slowdowns ensures laser levels remain accurate and dependable. Document all procedures to track equipment history and support warranty claims.

Conclusion

Taking advantage of the year-end slowdown for comprehensive maintenance can significantly impact future productivity and reliability. Contact our team for expert maintenance services and guidance to prepare your equipment for another successful year.

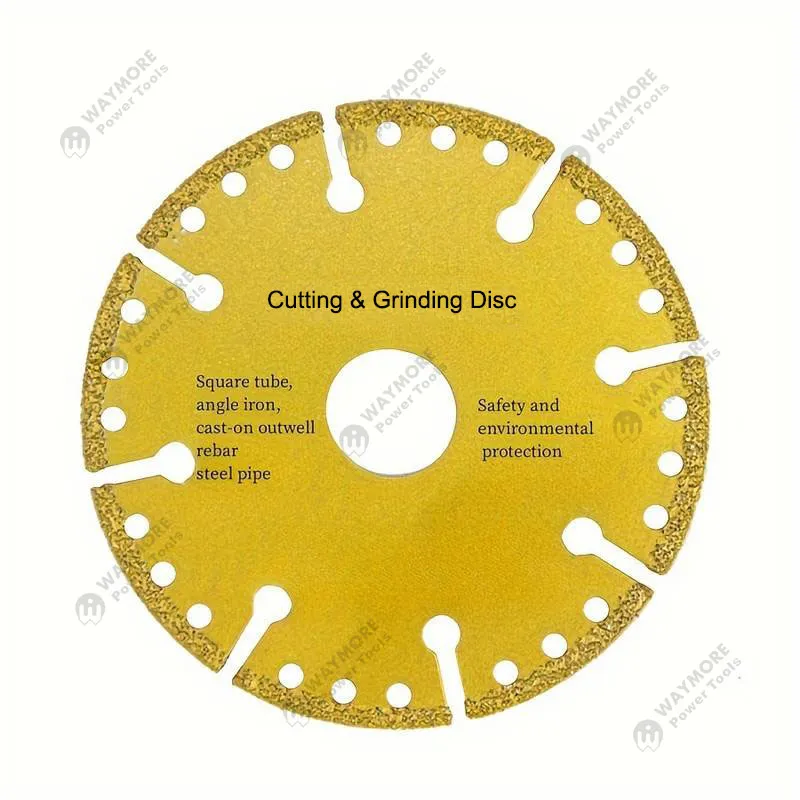

As our company continues to participate in this grand event, we remain committed to offering the best power tools and machinery solutions to meet the needs of our global partners. Whether you are a wholesaler, importer, or distributor, we are ready to collaborate and support your business growth.

If you are interested in our Power Tools, welcome to contact with us, and we are here to offer you best service and great products, thank you!

Contact: Daniel

Email: daniel@waymoretools.com

Website: www.waymoretools.com

Waymore Tools

Waymore Tools