Today's Insights: Creative Applications of Laser Levels - Advanced Guide for Industry Professionals

Introduction

In today's evolving construction landscape, laser levels have transcended their traditional role as simple leveling tools. As suppliers and distributors in the power tools industry, we're witnessing an increasing demand for specialized applications, particularly in creating precise geometric patterns. This comprehensive guide explores how professional-grade laser levels can be utilized for complex pattern work, with a special focus on U-shaped configurations that are becoming increasingly popular in modern construction projects.

Understanding Laser Level Types and Their Applications

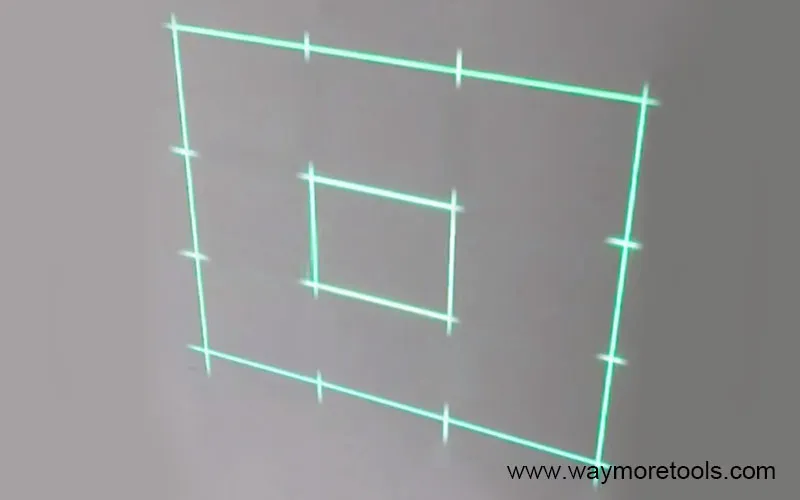

Today's construction industry demands versatility and precision in tool applications. Professional laser levels now come in three primary configurations: rotary laser levels, line laser levels, and dot laser levels. For creating complex patterns such as U-shaped lines, line laser levels have emerged as the preferred choice due to their superior versatility and precision in projecting both horizontal and vertical lines.

When advising our professional customers, we emphasize that modern line laser levels can project beams in both 180-degree and 360-degree patterns. This flexibility is crucial for contractors and creative professionals who need to tackle complex layout work. The ability to project clear, precise lines in multiple orientations makes these tools invaluable for sophisticated pattern creation.

Essential Equipment Configuration

Creating precise U-shaped patterns requires a specific combination of laser levels. Our experience shows that the most effective setup includes:

- Two 12-line laser levels for comprehensive coverage

- Two 2-line laser levels for vertical alignment

- Self-leveling capabilities for precise positioning

This configuration ensures complete coverage while maintaining the accuracy necessary for professional applications. The self-leveling feature is particularly valuable as it eliminates the need for time-consuming manual adjustments and ensures consistent results across multiple setups.

Advanced Pattern Creation Techniques

The key to successful pattern creation lies in controlling laser line visibility. Professional users can achieve precise control through strategic masking techniques using standard materials like masking tape. We recommend a systematic approach:

- Position the laser levels to create the basic grid pattern.

- Carefully apply masking tape to block unwanted lines, creating the desired U-shaped configuration.

This method maintains the laser level's inherent accuracy while allowing for customized pattern creation.

Mounting Solutions for Complex Patterns

Stable mounting is crucial for precise pattern creation. Professional laser levels should be equipped with:

- Heavy-duty tripods for stability

- Magnetic brackets for metal surface mounting

- Specialized clamps for various surfaces

- Multiple mounting points for complex configurations

The best laser levels incorporate various mounting features that enable hands-free operation while maintaining accuracy. For U-shaped patterns, we recommend using multiple secure mounting points to ensure perfect alignment throughout the project.

Optimizing Beam Visibility

When working with multiple laser levels, beam visibility becomes critical. Green laser beams offer superior visibility in well-lit environments, making them ideal for daytime work or brightly lit indoor spaces. However, for extended use with multiple lasers, red beams provide distinct advantages:

- Lower power consumption

- Extended battery life

- More cost-effective operation

- Reduced eye strain during prolonged use

We advise our customers to consider their specific working conditions when choosing between red and green beam options.

Maintaining Accuracy Through Proper Calibration

Professional results require maintaining precise calibration across all laser levels. Industry standards typically specify accuracy within ⅛-inch deviation at 30 feet. To ensure consistent results:

- Regularly check calibration on all units

- Follow manufacturer-recommended calibration procedures

- Document calibration checks for quality assurance

- Maintain proper storage and handling protocols

For pattern creation work, even slight calibration errors can compound into significant deviations, making regular verification essential.

Advanced Applications and Industry Solutions

The versatility of modern laser levels extends beyond basic construction applications. We're seeing increasing adoption in:

- Architectural design implementation

- Custom interior layouts

- Industrial pattern marking

- Creative professional applications

- Specialized construction projects

By understanding these advanced applications, suppliers can better serve customers who require precise pattern-creation capabilities.

Conclusion and Future Considerations

As the construction industry continues to evolve, the demand for precise pattern-creation capabilities will only increase. By maintaining an inventory of versatile, high-quality laser levels and necessary accessories, suppliers can position themselves to meet these emerging needs effectively.

Ready to elevate your laser level inventory with professional-grade solutions? Contact our team of specialists today to explore our comprehensive range of laser levels and accessories designed for both traditional construction applications and creative pattern work. We'll help you select the perfect combination of tools to meet your customers' diverse needs and stay ahead of industry demands.

As our company continues to participate in this grand event, we remain committed to offering the best power tools and machinery solutions to meet the needs of our global partners. Whether you are a wholesaler, importer, or distributor, we are ready to collaborate and support your business growth.

If you are interested in our Power Tools, welcome to contact with us, and we are here to offer you best service and great products, thank you!

Contact: Daniel

Email: daniel@waymoretools.com

Website: www.waymoretools.com

Waymore Tools

Waymore Tools