Today's Insights: When To Use an Impact Driver VS Drill: The ULTIMATE Guide

Summary

Impact drivers and drills serve different purposes: drills are designed for drilling holes, while impact drivers excel at driving fasteners. Both tools complement each other, and understanding when to use each can improve the efficiency of your projects.

Highlights

- 🔧 Tool Differences: Impact drivers feature a unique torque mechanism, while drills use gears to control speed.

- 🛠️ Chuck Types: Drills use a three-jaw chuck to accommodate various bits; impact drivers require 1/4-inch hex bits.

- ⚙️ Clutch Functionality: Drills often include a clutch for delicate work; impact drivers typically do not, increasing the risk of overdriving screws.

- ⏱️ Speed Control: Drills offer multiple gears to adjust speed and torque, while impact drivers rely primarily on variable trigger speed.

- 🛡️ Kickback Prevention: Impact drivers reduce kickback, providing safer operation.

- 🔊 Noise Levels: Impact drivers are louder than drills, which may be a consideration in certain environments.

- ⚡ Efficiency: Impact drivers generally deliver more torque for driving screws, making them the better choice for fastening tasks.

Key Insights

- 🔍 Understanding Mechanisms: Knowing how each tool works can help you choose the right tool for the job.

- 📏 Size Matters: Impact drivers are more compact, making them ideal for tight spaces.

- ⚡ Torque Advantage: Impact drivers offer superior torque, making them perfect for heavy-duty fastening tasks.

- 🛠️ Versatile Applications: Drills excel at drilling tasks, while impact drivers are ideal for driving fasteners.

- 🧰 Safety Features: Impact drivers' kickback prevention enhances safety and user confidence.

- 🔊 Noise Consideration: Impact drivers are louder, so noise-sensitive environments might require extra precautions.

- 🔄 Interchangeability: While some tasks can be done by both tools, understanding their strengths will help improve your efficiency.

Tool Differences

Both the drill and the impact driver are commonly found in combination sets, but their functionalities differ significantly. The drill's chuck spins continuously without interruption, while the impact driver employs a unique mechanism that generates high torque through a series of rapid impacts, especially useful for driving fasteners.

Torque and Clutch Differences

Drills offer more control over speed and torque with gear and clutch systems, allowing for more precision, especially in delicate work. On the other hand, impact drivers are designed for maximum torque without a clutch mechanism, which can lead to overdriving screws if not carefully monitored.

Chuck Types

Drills typically feature a three-jaw chuck, enabling the use of a variety of bits, while impact drivers use 1/4-inch hex bits that are specifically designed for high torque applications.

Size and Kickback

Impact drivers are generally more compact than drills, making them easier to use in confined spaces. Additionally, due to their design, they mitigate the risk of kickback, a safety issue that can occur with drills when the bit binds in the material.

Understanding the Impact Mechanism

The impact driver's unique mechanism involves a hammer and anvil system. When resistance is encountered, the hammer strikes the anvil to produce rotational impacts, enabling the tool to drive fasteners with more torque. This makes impact drivers much more efficient in driving large fasteners compared to drills.

Drilling Choices: When to Use Each Tool

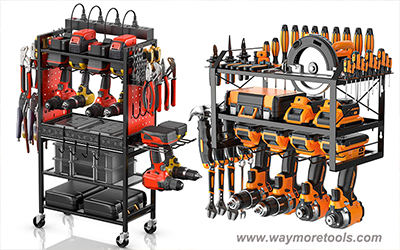

If you're drilling a hole in softer materials or need a large bit, a drill is typically the better choice due to its speed and control features. However, when working in tight spaces or when speed is of the essence, the impact driver can be more convenient. Some impact drivers, such as those from Waymore Tools, also support special adapters for added versatility.

Conclusion

In summary, while both drills and impact drivers have overlapping capabilities, they each excel in different areas. For drilling tasks, a drill is usually the better choice, but for driving fasteners—especially in tight spaces or when high torque is needed—an impact driver is invaluable. Understanding the strengths and weaknesses of each tool will help you make the right choice for your specific needs.

As our company continues to participate in this grand event, we remain committed to offering the best power tools and machinery solutions to meet the needs of our global partners. Whether you are a wholesaler, importer, or distributor, we are ready to collaborate and support your business growth.

If you are interested in our Power Tools, welcome to contact with us, and we are here to offer you best service and great products, thank you!

Contact: Daniel

Email: daniel@waymoretools.com

Website: www.waymoretools.com

Waymore Tools

Waymore Tools