Which do you choose - Drill vs Impact Driver

Table of Contents

- Choosing the Right Tool for Your Project: Drill vs Impact Driver

- Power and Torque: Comparing Drill and Impact Driver Capabilities

- Versatility and Applications: Exploring the Uses of Drill and Impact Driver

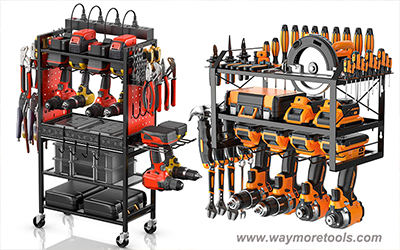

- Features and Accessories: Enhancing Functionality with Drill and Impact Driver

- Cost and Value: Evaluating the Investment in Drill vs Impact Driver

- Safety Considerations: Ensuring Proper Use of Drill and Impact Driver

- Conclusion

Choosing the Right Tool for Your Project: Drill vs Impact Driver

When embarking on a home improvement project, selecting the appropriate tool for the task at hand is crucial. Two commonly used power tools, the drill and the impact driver, offer distinct advantages and applications. Understanding their differences will empower you to make an informed decision based on your specific needs.

A drill, as its name suggests, is primarily designed for drilling holes in various materials. Its rotating motion allows for precise and controlled drilling, making it ideal for tasks such as creating pilot holes for screws, installing anchors, or drilling through wood, metal, or plastic. Drills typically come with adjustable speed settings, enabling you to match the speed to the material being drilled.

An impact driver, on the other hand, excels at driving screws and bolts. Its unique mechanism combines rotation with an impact force, delivering powerful blows that make it easier to drive fasteners into dense materials such as hardwood, concrete, or metal. Impact drivers are particularly useful for tasks that require high torque, such as tightening lug nuts on a car or driving long screws into framing lumber.

Power and Torque: Comparing Drill and Impact Driver Capabilities

When selecting a power tool for drilling or driving tasks, understanding the differences between drills and impact drivers is crucial. Both tools offer distinct capabilities, making them suitable for specific applications.

Drills excel in creating precise holes in various materials. Their rotating motion allows for smooth and controlled drilling. However, drills lack the torque necessary for driving screws or bolts into dense materials.

Impact drivers, on the other hand, are designed for high-torque applications. They combine a rotating motion with an impact mechanism that delivers powerful blows to drive fasteners. This makes them ideal for tasks such as driving screws into wood, metal, or concrete.

Versatility and Applications: Exploring the Uses of Drill and Impact Driver

When it comes to power tools, drills and impact drivers are two essential tools for any home improvement enthusiast or professional. While both tools share some similarities, they have distinct characteristics that make them suitable for different applications. Understanding the versatility and applications of each tool is crucial for making an informed decision when choosing the right one for your project.

Drills are versatile tools designed for a wide range of tasks, including drilling holes in various materials such as wood, metal, and plastic. They are also commonly used for driving screws and mixing paint or other liquids. Drills typically have a chuck that allows for easy bit changes, making them adaptable to different tasks.

Impact drivers, on the other hand, are specifically designed for driving screws and bolts. They utilize a hammering action that provides additional torque, making them ideal for tasks that require high fastening power. Impact drivers are particularly useful for driving screws into dense materials such as hardwood or metal.

Features and Accessories: Enhancing Functionality with Drill and Impact Driver

When embarking on home improvement projects or tackling repairs, the choice between a drill and an impact driver can be crucial. Both tools offer distinct advantages, and understanding their capabilities is essential for selecting the right one for the job.

Drills excel in creating precise holes in various materials, including wood, metal, and plastic. Their variable speed settings allow for controlled drilling, ensuring clean and accurate results. Additionally, drills can be equipped with a wide range of bits, making them versatile for tasks such as driving screws, mixing paint, and sanding.

Impact drivers, on the other hand, are specifically designed for driving screws and bolts. They utilize a hammering action that delivers high torque, making them ideal for fastening into dense materials like concrete or metal. Impact drivers are particularly useful for repetitive screw-driving tasks, as they reduce fatigue and increase efficiency.

Cost and Value: Evaluating the Investment in Drill vs Impact Driver

When embarking on home improvement projects or tackling repairs, the choice between a drill and an impact driver can be a crucial one. Both tools offer distinct advantages and drawbacks, and understanding their respective capabilities is essential for making an informed decision.

The primary difference between a drill and an impact driver lies in their intended purpose. Drills are designed for creating holes in various materials, while impact drivers excel at driving screws and other fasteners. Impact drivers deliver a high-torque impact that helps to break through tough materials and prevent stripping screws.

Impact drivers typically offer higher torque than drills, making them more suitable for demanding tasks. This increased torque allows them to drive screws into dense materials, such as hardwood or metal, with ease. Drills, on the other hand, provide sufficient torque for most drilling applications, including creating holes in wood, plastic, and drywall.

Safety Considerations: Ensuring Proper Use of Drill and Impact Driver

When selecting between a drill and an impact driver, safety should be paramount. Both tools possess unique capabilities and potential hazards, necessitating an understanding of their proper use.

Drills excel in creating precise holes in various materials. Their rotating motion allows for controlled drilling, making them ideal for tasks such as installing screws, driving nails, and boring holes. However, drills lack the impact force required for heavy-duty applications.

Impact drivers, on the other hand, deliver high-torque impacts that make them indispensable for driving large screws, bolts, and lag bolts. Their hammering action provides the necessary force to penetrate dense materials, such as concrete and metal. However, impact drivers can be more challenging to control, increasing the risk of injury.

Conclusion

The choice between a drill and an impact driver depends on the specific task at hand. For general drilling tasks, a drill is sufficient. However, for driving screws or bolts into hard materials, an impact driver provides superior power and efficiency. If versatility is a priority, a drill with an impact driver mode offers the best of both worlds. Ultimately, the best choice depends on the user's individual needs and preferences.

Waymore Tools

Waymore Tools

Leave a Comment